For many years, wood-frame construction has been pro-

viding Canadians with high-quality, affordable housing.

This goes from town houses to multi-storey apartment

buildings, and from single-family bungalows to large

luxury houses.

The secret of this success lies with many factors, and speed of erection is

definitely one of them, not to mention the fact that occupants can move

into the building almost as soon as it is completed. In addition, wood-

frame construction uses a renewable resource; and its design flexibility

allows for efficient building concepts in terms of energy conservation as

well as safety and reliability under extreme conditions such as earthquakes.

North American fire-loss statistics reveal that death and injury in build-

ing fires are usually caused by smoke inhalation, and occur long before

structural failure. With large numbers of residential fires resulting from

the cooking of meals or the ignition of furnishings by cigarettes, it is

clear that people are just as safe in a wood-frame house as they would

be in a house built of stone, bricks, steel or any other material.

Research and experience confirm that fire safety in a house or apartment

has little to do with the combustibility of the structural materials used

in its construction. In fact, the occupants' safety is far more dependent

on their own awareness of fire hazards (open flames, etc.), the contents

of their homes, and the fire protection measures designed into the build-

ing. The main objectives of fire protection are a) to confine any fire to its

area of origin and ensure that the structural integrity of the building is

maintained during evacuation, and b) to ensure that measures are in

place to allow for the safe exit of all occupants.

The intent of this brochure is to provide some background on fire safe

construction concepts, as well as examples of wood-based light-frame

building systems designed to maximize fire safety.

Wood-frame Construction,

Fire Resistance and

Sound Transmission

Wood frame single family construction

with exterior brick

Wood frame multi-family construction

Wood-frame Construction,

Fire Resistance and Sound Transmission

Fire resistance

in single-family construction

For single-family houses, Canadian build-

ing codes contain measures to limit the

risk of fires spreading from one house to

another. These measures usually involve

minimum permitted distances between

houses, combined with restrictions on cladding com-

bustibility and opening sizes (windows or doors) in crit-

ical walls. Regardless of the materials used in construc-

tion of the dwellings, electrical and heating systems must

be installed and maintained according to approved pro-

cedures; and minimum permitted distances are pre-

scribed between combustible materials and heat sources

(cooking range to kitchen cabinets, wood stove to wall

lining, etc.). However, Canadian codes do not require

fire-rated floors or walls in single-family construction. It

is assumed that people within an individual dwelling are

generally aware of each other's activities and will react in

a mutually responsible manner to the occurrence of fire

and smoke alarms within their dwelling. Regular grades

of gypsum board used to sheath walls and ceilings offer

meaningful measures of fire containment and protection

of wood structural members while contributing time for

occupants to safely evacuate the house; basements are

frequently left without a ceiling. In countries where

building codes may require fire-rated construction in

single-family houses, the techniques described for multi-

family construction would be equally applicable.

Fire resistance

in multi-family construction

In Canada as in most countries, fire-resistance-

rated building assemblies in multi-family

dwellings are used to prevent, for a certain

period of time, the spread of fire, smoke

and heat from one unit to another (essen-

tially through walls and floors), and to ensure that the

structural integrity of the building is maintained. Fire-

resistance-rated walls and floors are also required for exit

corridors and stairways to ensure that people can safely

leave the building in the event of a fire.

[photo of multi-storey multi-family building]

Fire-resistance rated gypsum board

The fire-resistance of wood-frame assemblies (walls or

floors) depends almost entirely on the gypsum board

(also called wallboard or plasterboard) used to shield

structural wood members from the effects of heat. When

exposed to fire, the gypsum absorbs large amounts of

heat as its water content is released.

There are different kinds of gypsum board on the market,

but the construction of fire-rated wood-frame assemblies

requires specially manufactured fire-rated panels. These

panels contain, among other constituents, glass fibres

that improve their dimensional stability and nail-head

pull-through resistance, allowing them to remain in

place for longer periods of time when exposed to fire.

Specific construction practices and design details are used

to maximize the length of time that the gypsum board

remains in place.

2

Wood frame single family construction

with wood exterior siding

Wood frame multi-story condominium units, in construction

Fire-resistance ratings provide a measure of the time that an

assembly will withstand the passage of flame and smoke, and

the transmission of heat when exposed to fire under specified

fire conditions, including structural loads if applicable. They

are generally based on tests conducted in conformance with

one of two standards: International Standards Organisation

(ISO); ISO 834 Fire Resistance Tests Elements of Building

Construction, or American Standard Testing Method

(ASTM); ASTM E-119 Standard Test Methods for Fire Tests of

Building Construction and Materials. Fortunately, the fire

exposures prescribed in the two standards are essentially iden-

tical. Therefore, fire-resistance ratings determined in one coun-

try are often accepted by building officials in others.

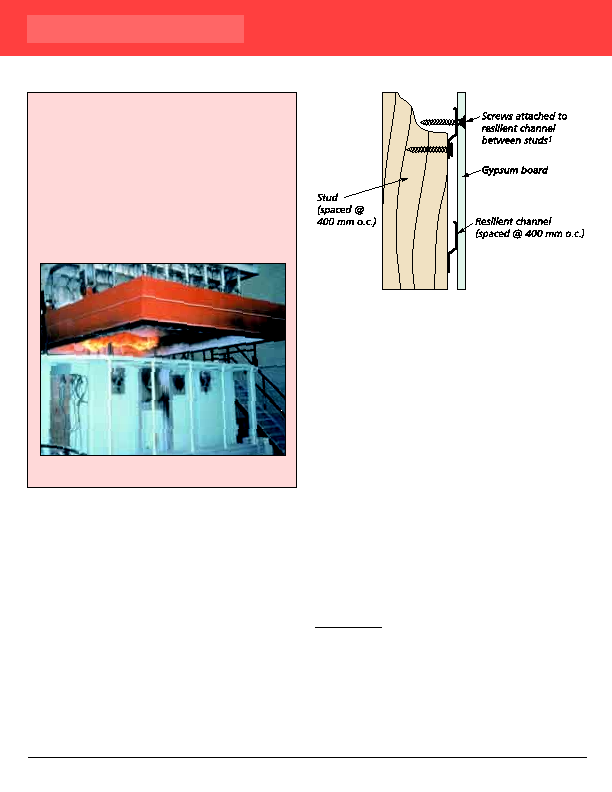

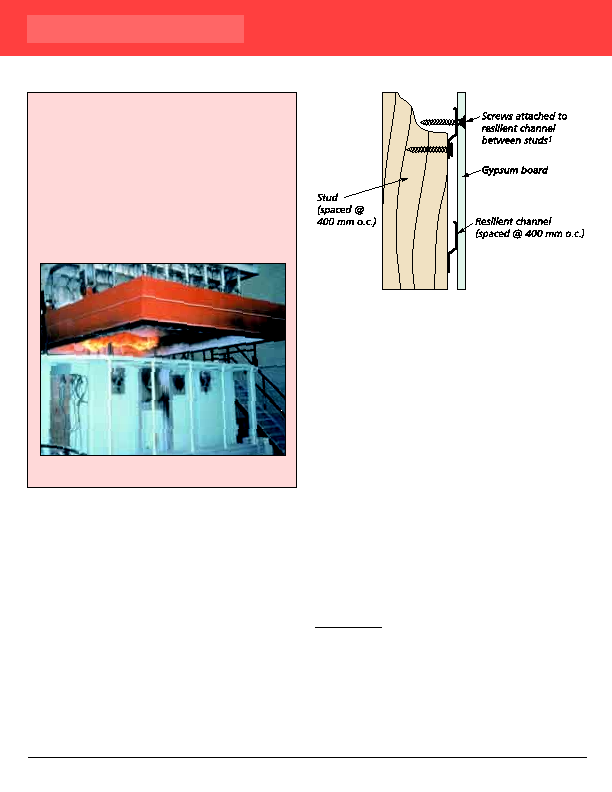

Fastening gypsum board to walls or

ceilings

Attaching gypsum board to walls or ceilings using

resilient metal channels reduces sound transmission as

well as the stresses on gypsum caused by movement in

the joists or studs during a fire. Keeping wallboard fas-

teners 38 to 50 mm from the edge of the panel allows

much more shrinkage to occur before the panel pulls

away from the fasteners. The fasteners holding the gyp-

sum board in place on a wall or ceiling should be spaced

no further than 200 mm apart along each resilient metal

channel, stud or joist. The screws used to attach gypsum

board to resilient metal channels should be long enough

to penetrate 10 mm through the channel. The screws

used to attach resilient metal channels to the wall studs

or ceiling joists, or to attach gypsum board directly to the

studs or joists should penetrate 32 mm into the wood

members. If nails are used, these should penetrate at least

45 mm into the wood members. Screws used to fasten

gypsum board to resilient channels should never come

into contact with structural members

2

.

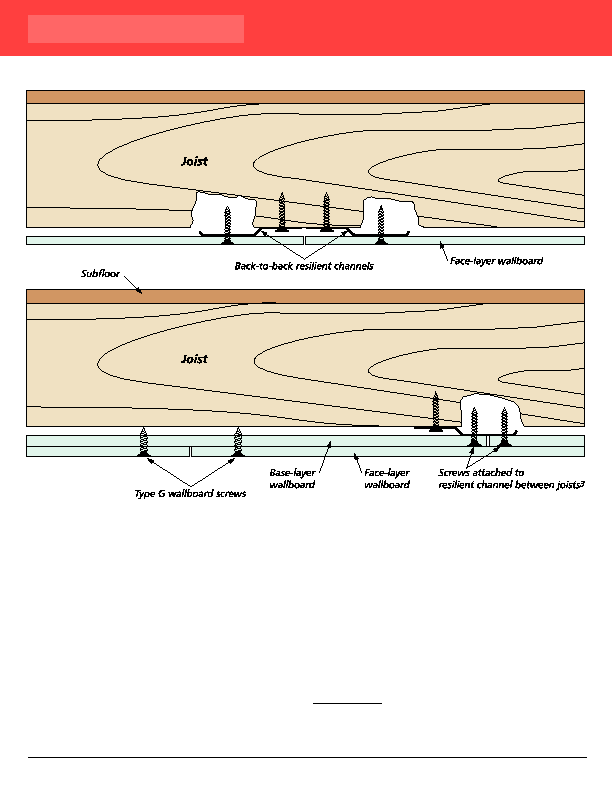

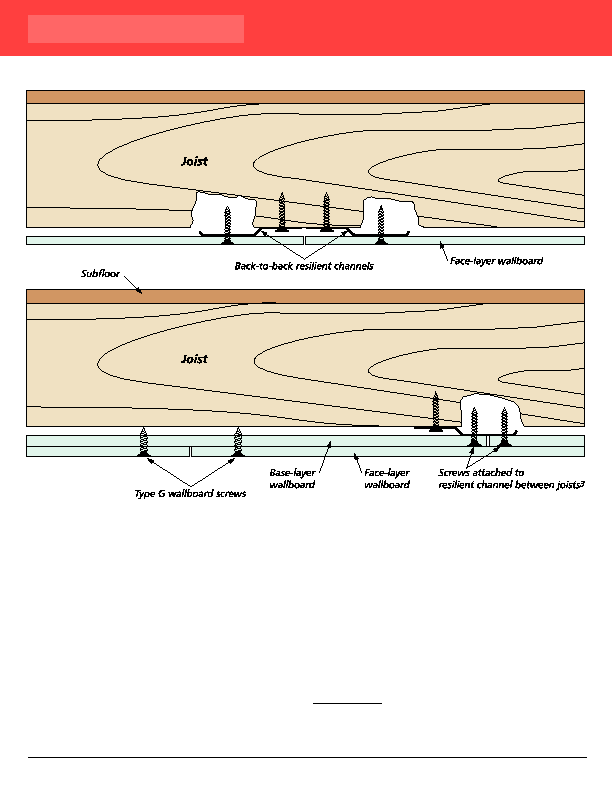

For ceilings consisting of a single layer of gypsum board,

this design detail requires two resilient channels to be

placed back-to-back at joints between the butt ends of

adjacent gypsum panels (See Figure at top of next page).

For ceilings consisting of two layers of gypsum board,

there is no need to keep the fasteners back from the butt-

end edges of the base layer, but they should be kept 38 to

50 mm from the butt-end edges of each panel in the face

layer. The easiest way to do this is to fasten the butt-ends

of the face layer of gypsum board to the base layer using

Type G wallboard screws (thicker shank, coarser thread).

When ceilings consist of two layers of gypsum board,

joints between adjacent panels of gypsum board in the

face layer should be centred on the panels in the base

layer.

1

The screws used to attach the gypsum board to resilient channels must be

located away from the studs, as any direct contact with structural members

would create a path for sound transmission.

2

Additional information on gypsum installation for fire resistance and

sound control is available from the Canada Mortgage and Housing

Corporation (CMHC), Ottawa, Canada, and the Gypsum Association,

Washington, D.C., USA.

Wood-frame Construction,

Fire Resistance and Sound Transmission

3

Typical gypsum board installation on walls, with resilient channels

Fire chamber at the National Research Council of Canada

Wood-frame Construction,

Fire Resistance and Sound Transmission

Use of insulation in floors or walls

separating different dwellings

Placing glass-fibre or rock-fibre insulation between the

joists of wood-frame floor assemblies reduces sound

transmission. It also restricts heat transfer from the ceil-

ing into the joist cavities and, for a time, shields the sides

of the joists and subfloor from the effects of the fire.

However, the additional heat retained in the gypsum

board reduces the time it will remain in place. Once the

gypsum board falls from the ceiling, the insulation is

exposed directly to the fire. Glass-fibre insulation melts

after a few minutes. Rock-fibre insulation does not melt

and only shrinks slightly; bats of rock-fibre insulation

4

3

The screws used to attach the gypsum board to resilient channels must be

located away from the joists, as any direct contact with structural members

would create a path for sound transmission.

Typical gypsum board installation on ceilings single layer on

resilient channels (top) double layer on resilient channels

(bottom)

supported between the joists by the resilient channels

will therefore shield the joists and subfloor from fire for

a significant period of time after the ceiling falls away.

Insulating materials are installed in close contact with

the sides of the studs or joists, as gaps would allow hot

fire gases to penetrate into the cavity and attack the sides

of the wood members.

Fire-rated wall construction

In multi-family construction, load-bearing walls (sup-

porting upper floors) and party walls (separating two

dwelling units, or public corridors and exits from the rest

of the building) are designed to provide specific fire-

resistance ratings as per applicable building codes.

Fire-rated gypsum board is available in two thicknesses:

12.7 mm and 15.9 mm. The thicker panels present a

somewhat better thermal barrier and allow significantly

greater fire resistance. On the other hand, the stud spac-

ing (400 mm or 600 mm on-centre) does not signifi-

cantly change the fire resistance of a wall assembly.

Horizontal installation of gypsum board (i.e. with the

long direction perpendicular to the studs) results in

unbacked horizontal joints. Since the joints between gyp-

sum board panels are weak points in fire-resistance rated

walls, the panels should be installed vertically so joints

may be centred on studs. There are two exceptions: 1) if

wall cavities are filled with rock-fibre insulation, and

2) if the wall includes a double layer of gypsum board

(with the joints in the face layer offset from those in the

base layer); then, the gypsum board may be applied in

either direction.

Some countries' building codes require horizontal block-

ing at 400 or 600 mm spacing between the studs. These

components provide additional opportunities to fasten

the gypsum panels to the wall when resilient channels

are not used, thereby increasing the fire resistance of the

assembly. They also serve to increase the fire resistance of

taller walls, where the mode of failure is likely to be due

to wall buckling.

In the construction of shear walls, plywood or oriented-

strandboard (OSB) panels nailed to the studs and cov-

ered with gypsum board add 5 to 10 minutes to the over-

all fire resistance of the assembly, depending on which

side of the wall they are placed (ambient or fire-exposed

side). There are no significant differences between the

fire-resistance ratings of wall assemblies constructed with

plywood or OSB shear panels.

Firewalls are fire separations of non-combustible construction.

They have fire-resistance ratings as prescribed in building

codes, and structural properties such that they will remain

intact under fire conditions for the required fire-rated time.

Firewalls are commonly used to divide row-housing blocks into

smaller groups and resist the spread of fire from one group to

another. They are also used to divide a large building into

smaller units where standard fire protection measures are

applicable.

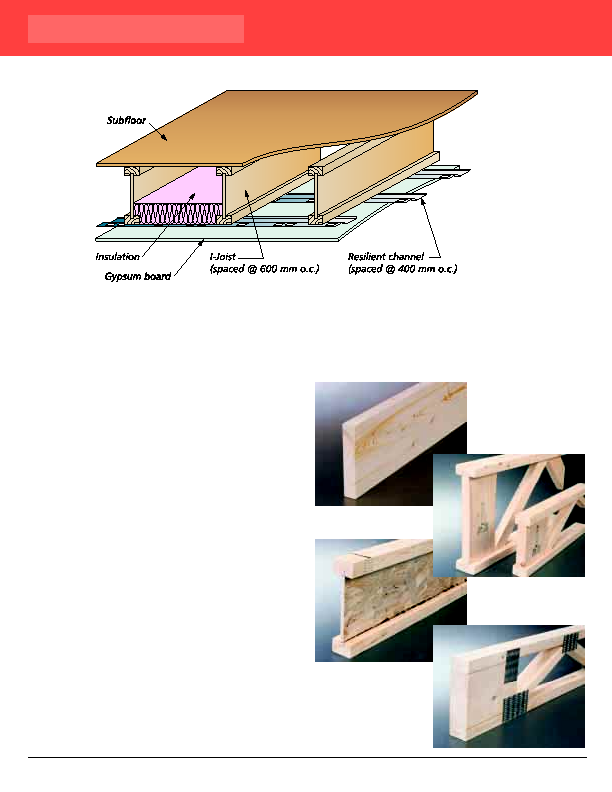

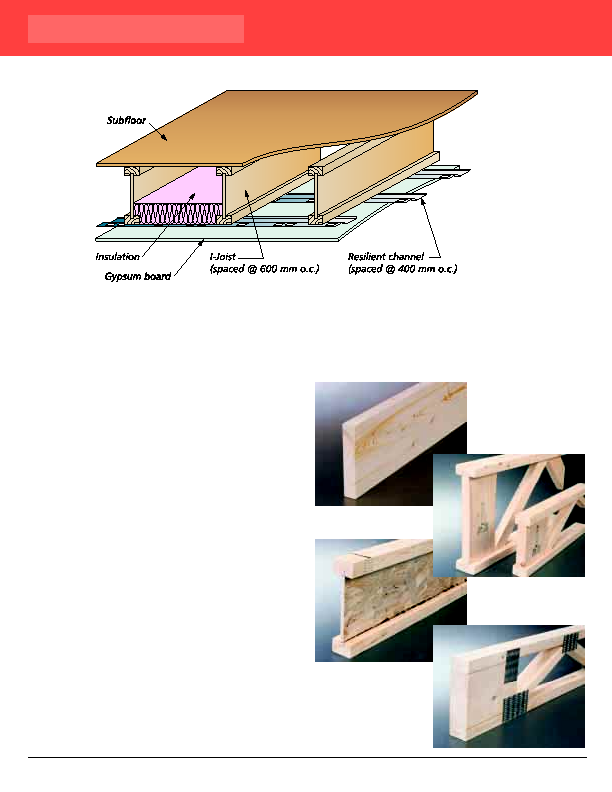

Fire-rated floor construction

Fire-rated floors, used in most types of multi-storey,

multi-family buildings, are constructed with joists, a ceil-

ing and a subfloor.

In ceiling applications, there is little advantage in using

15.9-mm gypsum board panels as their greater weight

causes them to fall off during fires at about the same time

as the thinner panels, so that the fire resistance of the

floor assembly is not substantially increased.

When the gypsum board ceiling is attached with resilient

metal channels, the use of blocking or bridging between

the joists will not enhance the fire resistance of a floor

assembly. If, on the other hand, the ceiling is attached

directly to the bottom of the joists, the use of blocking or

bridging between the joists along the centreline of a floor

assembly will reduce twisting of the joists during a fire,

thereby helping the gypsum board to remain in place

and protect the assembly.

When a gypsum board ceiling is attached directly to the

bottom of the joists, the fire resistance of that floor

assembly may be significantly reduced if the spacing

between the joists is increased (from 400 to 600 mm, for

example) because of the corresponding increase in dis-

tances between the rows of fasteners. However, if the gyp-

sum board is attached to the joists through resilient

metal channels spaced at 400 mm on-centre, increasing

the joist spacing may actually increase the fire resistance

rating of the assembly because the structural loads are

reduced and wider joist spacing requires a thicker

subfloor.

Wood-frame Construction,

Fire Resistance and Sound Transmission

5

Wood-frame Construction,

Fire Resistance and Sound Transmission

Subfloors usually consist of 1220 mm x 2440 mm pan-

els, either tongued-and-grooved plywood or OSB. The

long directions of the panels are oriented perpendicular

to the joists. The 1220-mm butt ends of the panels are

centred on joists. Floor assemblies with joists spaced

400 mm on-centre are constructed with 15.9-mm thick

panels; those with joists spaced 600 mm on-centre use

19.0-mm panels. There are no significant differences

between the fire resistance rating of floor assemblies con-

structed with plywood or OSB.

For a given floor span, the fire resistance of a floor assem-

bly constructed with I-Joists will generally be three to five

minutes less than that of a similar assembly constructed

with solid wood joists (which is insignificant in most sit-

uations). This can be attributed to the thinner profile of

the structural members, particularly the webs. Overall,

there is no significant difference in the fire resistance of

I-Joists manufactured with laminated-veneer-lumber

(LVL) or solid lumber flanges; nor is there any significant

difference in the fire resistance of I-Joists manufactured

with plywood or OSB webs. Finally, there is no signifi-

cant difference in the fire performances of I-Joists of

identical profile fabricated by different manufacturers.

Fire resistance ratings for floor assemblies constructed

with parallel-chord wood trusses (glued or connected

with metal or gusset plates) differ very little from those

for floors constructed with solid wood joists. While fail-

ure of wood trusses in fires usually results from the teeth

of the gusset plates pulling out of charred wood in the

bottom chord, the metal teeth do not accelerate char for-

mation in the underlying lumber.

Finally, there is no scientific evidence to support the

anecdotal claims that floors constructed with wood

I-Joists or metal-plate-connected wood trusses fail cata-

strophically and without warning during fires.

6

Typical fire-rated floor assembly. Subfloor may be OSB or plywood. Note resilient channels supporting the ceiling.

Solid wood joist

Open web finger

joined wood trusses

Metal plate connected

wood truss

I-Joist

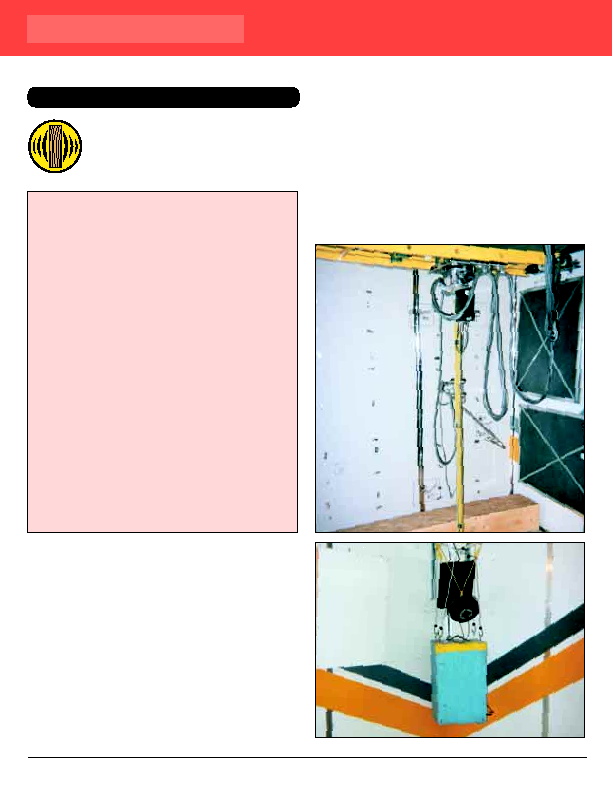

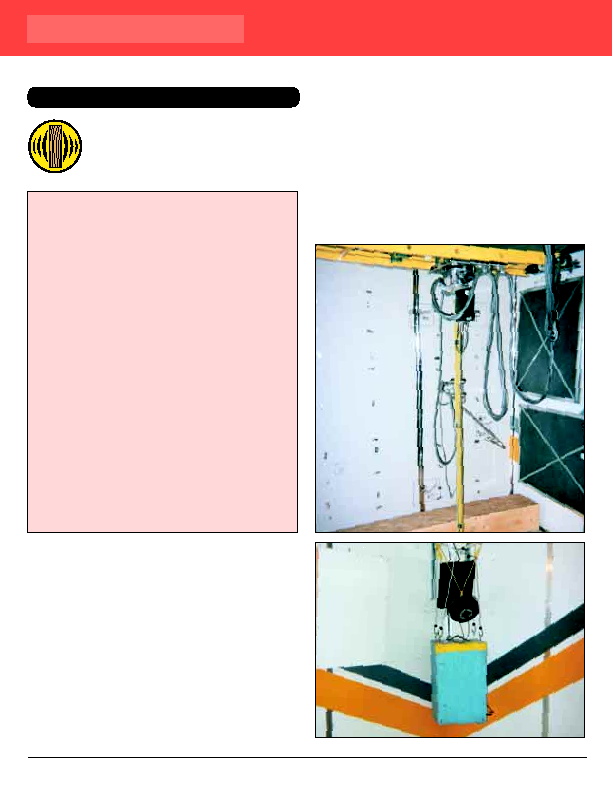

Sound transmission

Wood-frame construction is particularly

efficient in row houses and small apart-

ment buildings where high levels of sound

insulation are desired between adjoining

dwelling units.

In Canada, airborne-sound-transmission measurements are

made in accordance with ASTM E 90 Standard Test Method

for Laboratory Measurement of Airborne Sound

Transmission Loss of Building Partitions. Sound-transmission

class (STC) is determined in accordance with ASTM E 413

Standard Classification for Rating Sound Insulation.

Transmission of impact sound through floors is measured in

accordance with ASTM E 492 Standard Test Method for

Laboratory Measurement of Impact Sound Transmission

through Floor-ceiling Assemblies Using the Tapping

Machine. Impact-insulation class (IIC) is calculated accord-

ing to ASTM E 989 Standard Classification for

Determination of Impact Insulation Class.

The National Building Code of Canada currently specifies

STC 50 for partywalls in multifamily dwellings. However,

individual sensitivities to noise differ, in terms of both volume

and frequency ranges. Researchers at the National Research

Council Canada suggest that music or sounds from a television

set could be transmitted through a wall with STC 45, but that

only a bit of the base beating might be heard if the STC of the

wall was 50. Following a number of homeowner acoustic-

comfort surveys, Canada Mortgage and Housing Corporation

identified the following sound-insulation objectives for multi-

family buildings: STC >55 for inter-unit walls and floors,

impact insulation class (IIC) >55 for inter-unit "hard" floors

and IIC >65 for inter-unit carpeted floors.

The reduction of sound transmission between dwelling

units relies on three factors: 1) decoupling the two sides

of walls or floors from each other; 2) increasing the

assembly's overall mass; and 3) filling the joist or stud

cavities with sound-absorbing insulation. Resilient metal

channels used to attach gypsum board to wood-frame

assemblies, double layers of gypsum in ceilings and

walls, and insulation in the wall or floor cavities simulta-

neously enhance fire resistance and minimize sound

transmission. Furthermore, wood-frame construction

does not present the impact-noise transmission prob-

lems commonly noted with concrete construction.

Wood-frame Construction,

Fire Resistance and Sound Transmission

7

Acoustic chambers at the National Research Council of Canada

8

Wood-frame Construction,

Fire Resistance and Sound Transmission

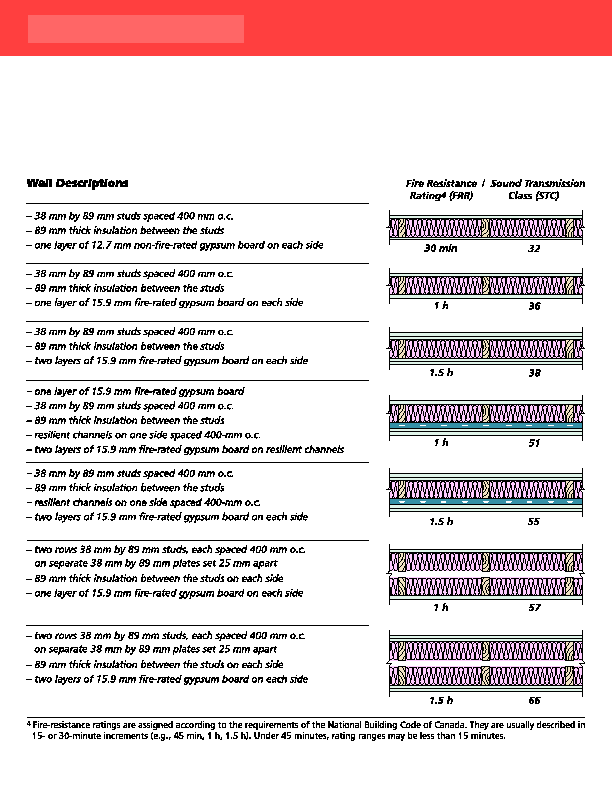

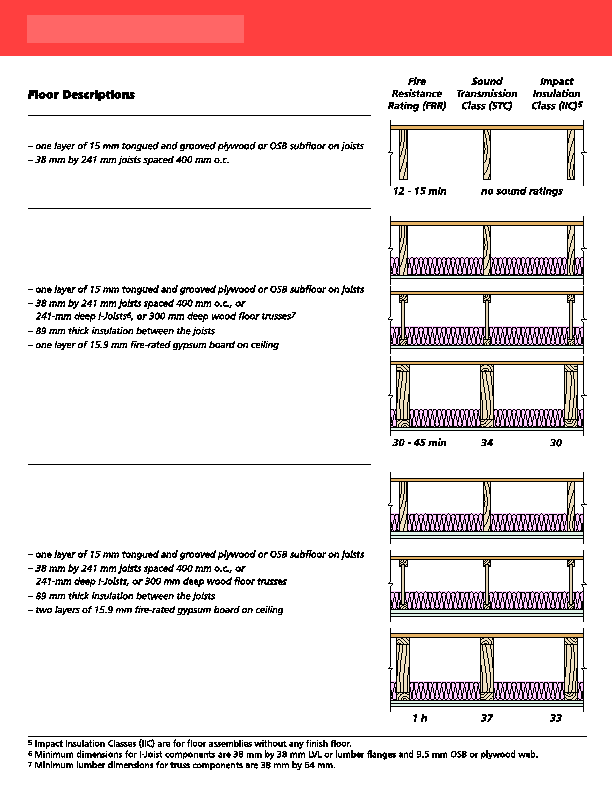

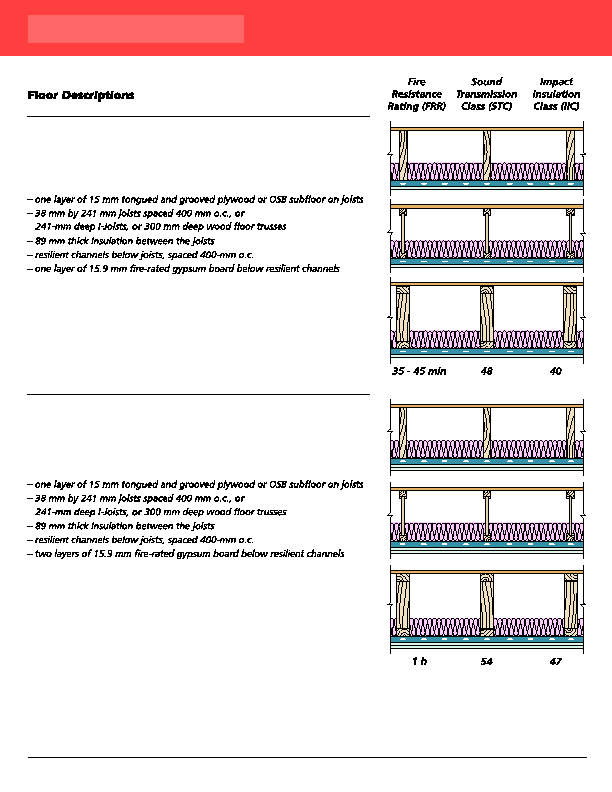

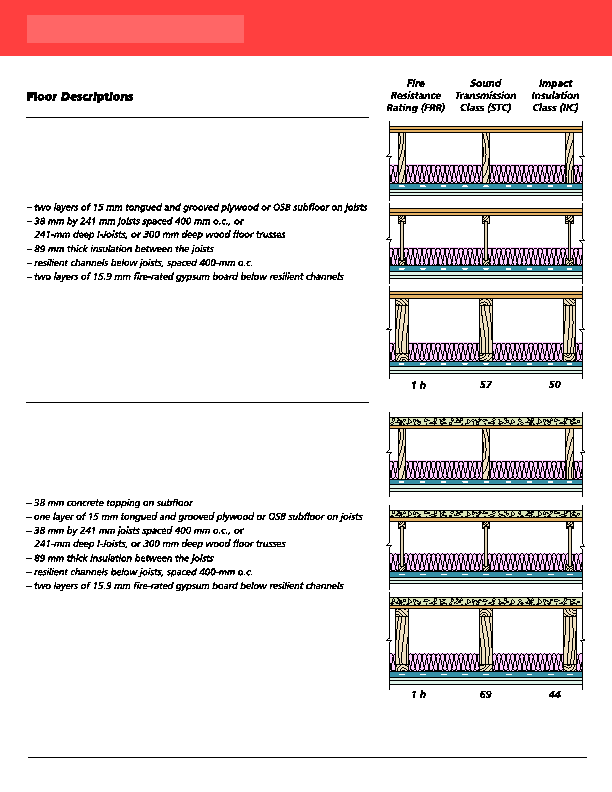

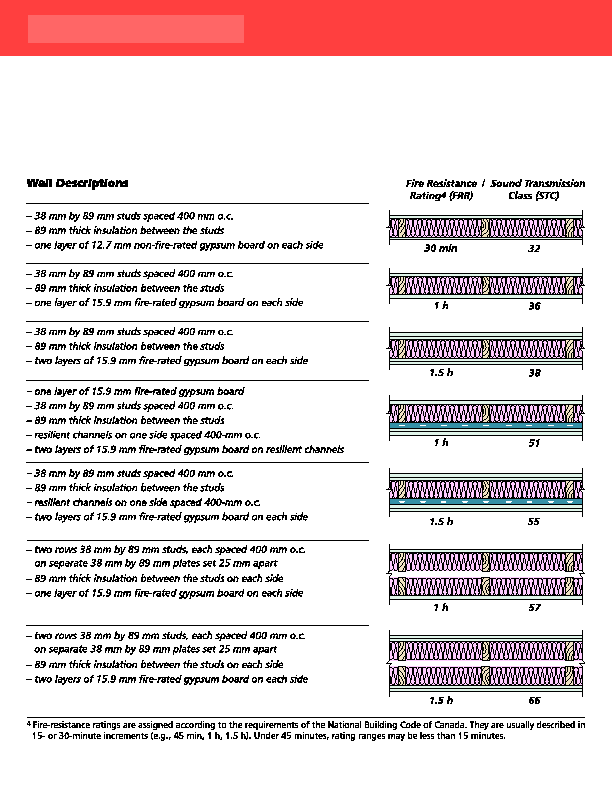

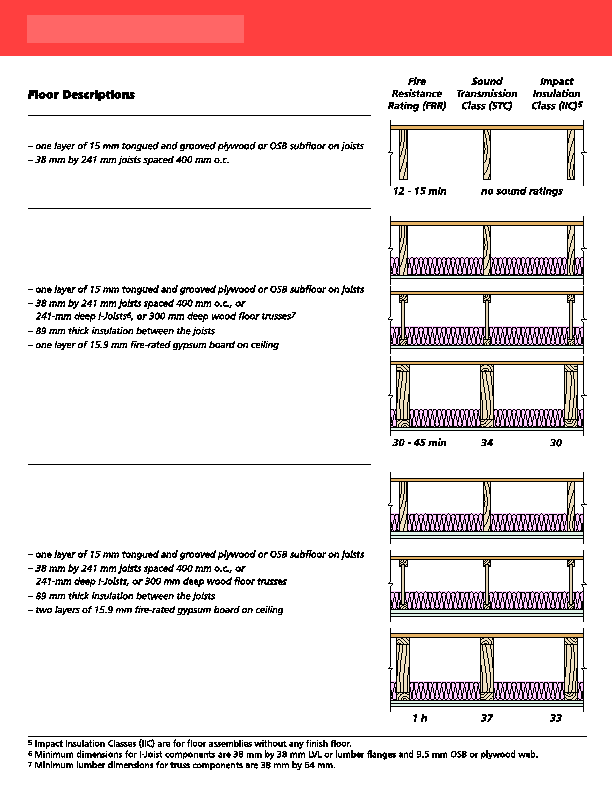

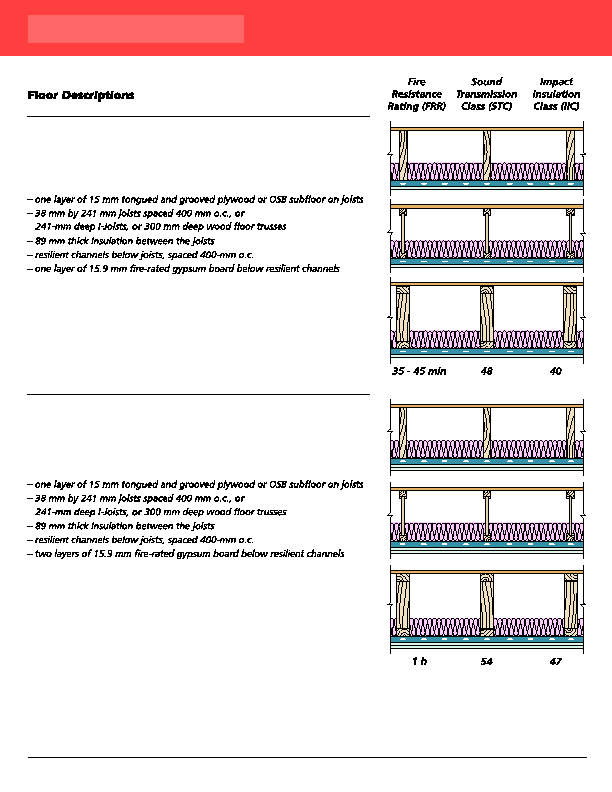

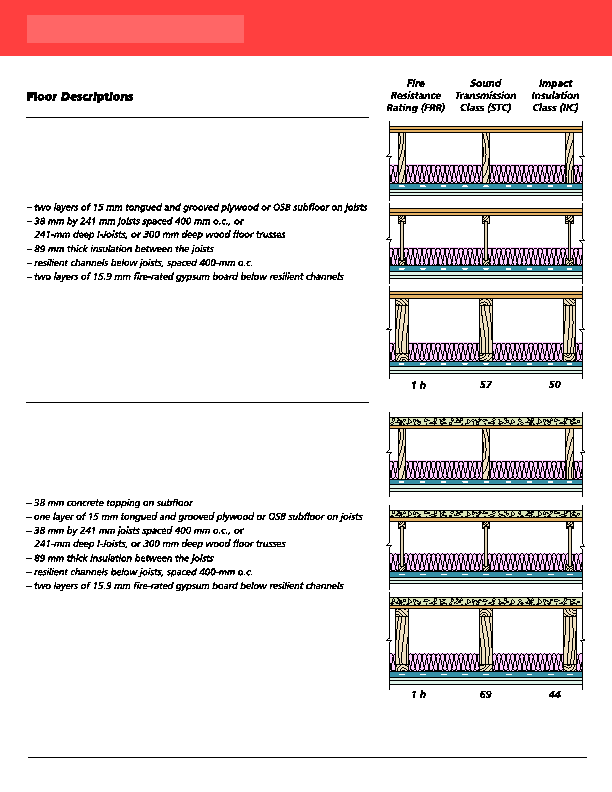

Examples of fire-rated assemblies

The following are examples of sound-transmission-class

(STC), impact insulation class (IIC) and fire-resistance

ratings assigned to specific wood-frame walls and floor

designs approved by the National Building Code of

Canada (NBCC). Many other designs exist to achieve

similar ratings.

9

Wood-frame Construction,

Fire Resistance and Sound Transmission

10

Wood-frame Construction,

Fire Resistance and Sound Transmission

Wood-frame Construction,

Fire Resistance and Sound Transmission

11

Wood-frame Construction,

Fire Resistance and Sound Transmission

12

Forintek is Canada's wood products research insti-

tute. A not-for-profit independent organization,

Forintek has a history, dating back to 1913, of pro-

viding leading-edge technical support to the wood

products industry. Forintek is North America's fore-

most industry-funded fire research organization for

wood construction systems. For more information:

www.forintek.ca

Canada Mortgage and Housing Corporation is the

Federal Government's housing agency. For over 50

years, CMHC has been helping provide Canadians

with housing quality, affordability and choice. CMHC

is also the Canadian housing industry's export partner,

bringing Canadian expertise to foreign markets. In

addition, CMHC is Canada's largest publisher of hous-

ing information. For more information: www.cmhc.ca

The Quebec Housing Corporation (Société d'habitation

du Québec) is the government agency responsible for all

matters related to housing in the province. Its mandate

covers primarily social housing and home improvement

activities. The Corporation also supports research activi-

ties in collaboration with a variety of partners as well

as the development and promotion of provincial

expertise in housing both in Quebec and abroad.

Tel.: 1-800-463-4315. Website: www.shq.gouv.qc.ca

©2002 Forintek Canada Corp., Société d'habitation du Québec and Canada Mortgage and Housing Corporation.

In conclusion

The fire performance of wood-frame construction is

based on many years of North American experience. It has

been documented through extensive testing, including

tests on full-size buildings.

Fire loss statistics and research demonstrate that people

are just as safe from fire in a wood-frame house, whether

single family or low-rise multi-family, as they would be in

houses built with any other material. Whatever the mate-

rial used, the fire protection measures laid out by modern

building codes such as the National Building Code of

Canada ensure adequate building integrity and safe evac-

uation for all occupants.

Wood-frame construction also provides a superior level

of comfort with respect to sound transmission, and it can

be designed to accommodate the broadest range of cli-

matic, cultural, regulatory and economic conditions.

Housing units exported from Canada are designed to

meet clients' performance requirements anywhere in the

world.

For more information

Fire Safety Design in Buildings is a reference for applying

the fire safety requirements of the National Building Code

of Canada to building design. This publication is available

from the Canadian Wood Council. Tel.: 1-800-463-5091.

Website: www.cwc.ca

Ce document est aussi disponible en français.

Este documento se encuentra disponible también en español.